Thanks to its lightweight design and compact size, it is easily movable and transportable

Ready for quickroll (as option)

With the R3a, AMB picot opens the door to sheet metal rolling.

- 3 rolls

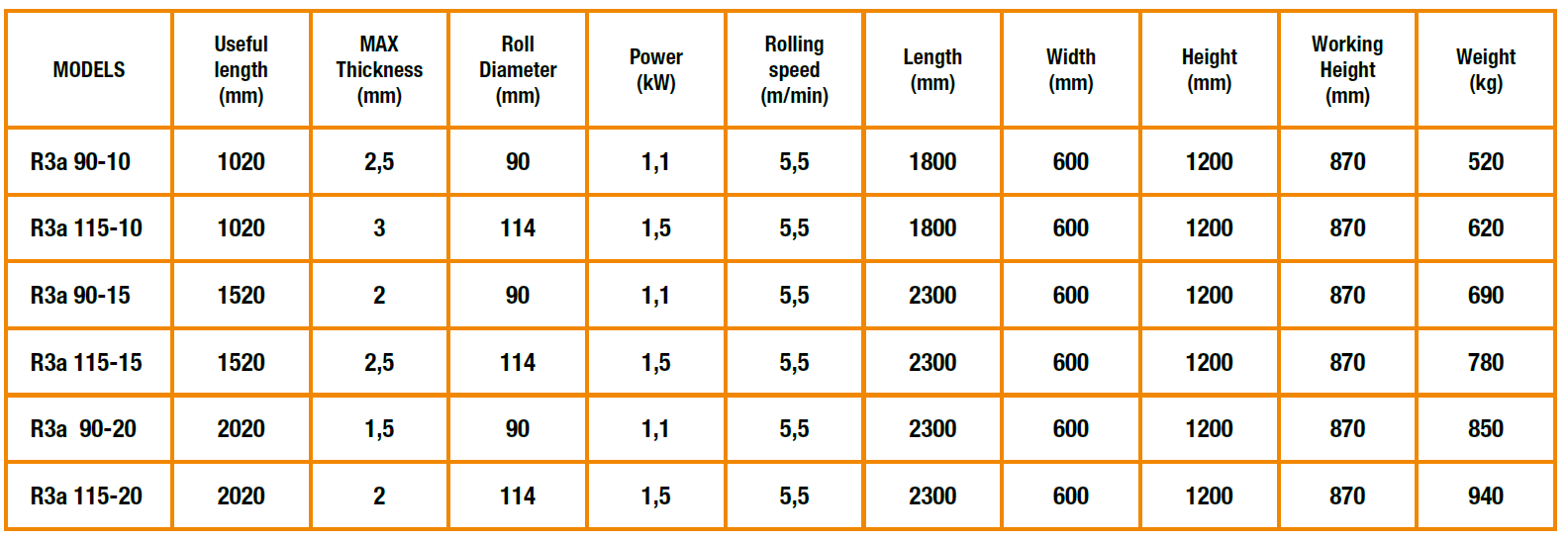

- 1 to 5 mm capacities (S235 steel )

- Useful length: 1-2 m

Electromechanical asymmetrical 3-rollers are an excellent entry point into the world of sheet metal rolling. Designed to offer a good compromise between performance, ease of use and moderate cost, they are an ideal first investment for workshops wishing to familiarize themselves with this essential sheet metalworking process.

We recommend the R3a electromechanical asymmetrical sheet metal roller in particular for :

- unit work

- thin sheet metal

R3a: a new standard to support you in your industrial changes and challenges

- Rotation of the top and pinching roll by a geared motor with a brake.

- Cast iron fames mounted on a very rigid chassis.

- Side bending roll is moved using a manual wheel with its position indication.

- Roller rotation controlled by double safety pedal

- Bidirectional foot pedal for rotation control.. (An optional control panel with a touchscreen and a joystick for plate rotation control is available, providing real-time position display of the bending roll.)

- QuickRoll softwar as option. (roll-bending assistance software, providing you with successive positions of the bending roll,

adjusted based on your material, its thickness, and the desired diameter.)

R3a What are the advantages of SHEET BENDING MACHINE

with three asymmetrical roller technology

01

2 powered rollers

One motor (gearmotor) per roller as standard. Our machines have been equipped with Danfoss motors for over 35 years. The rotation of the rollers is factory-synchronised by a hydraulic system that prevents any variation over time.

Benefits: maximum torque, optimised efficiency, synchronised speed, reliability.

Note: Our competitors only have one or two powered rollers as standard.

02

Special architecture: design for identical roller diameters

To guarantee the best performance in terms of bending and deformation of the part, we have three rollers of identical diameter.

The benefits: perfect geometry in the bending profile and better machine capacity.

Note: Our competitors’ lateral rollers have much smaller diameters -> reduced capacity

-> up to 30% additional bending.

03

Linear guide system

An incredibly useful technology, with no friction and excellent performance in all operating modes: cylindrical and conical rolling. It’s also a strategic choice for optimised prebending (on three- and four-roller machines)

Benefits: maximum efficiency of the hydraulic power, no wear.

Note: The planetary guide system used by our competitors is a low-cost solution

-> up to 30% loss of power and additional wear.

04

Bronze Bearing Technology

All of our machines are equipped with bronze bearings that accept high loads during rolling operations.

This technology is unrivalled in terms of both its capabilities and its longevity! Greasing is centralised and requires no maintenance.

Note: Our competitors use roller bearings (more economical, but unable to withstand heavy loading).

CONTROL

The standard version of the R3a includes a bidirectional foot pedal.

An optional control panel with a touchscreen and a joystick for plate rotation control is available, providing real-time position display of the bending roll..

SOFTWARE

As option: discover quickroll, the roll-bending assistance software, providing you with successive positions of the bending roll, adjusted based on your material.

This software is also available on PC tablets..

CONTROL EQUIPEMENT

Available options

*Machines capacity are provided for information only, based on S235 steel type of material (Yield strength = 240 N/mm² = 34,800 Psi).