Know-how: roll plate bending machine design and manufacturing

Over 150 years of research and innovations to develop the most advanced bending and prebending machines…

All the

components of our bending machines

are designed and produced

in our workshops in Lentilly

Feedback

from our customers allows

our design office

to upgrade

its components

and technologies on a regular basis

KNOW-HOW AND EXPERIENCE

By combining the expertise of a brand possessing more than a century of experience of building machine tools with recent technological developments, AMB Picot provides its customers with bending and forming tools that are specifically adapted to their needs.

The development of both the Company and its products is based on four principles, to meet the needs of its demanding customers:

Reliability, Quality, User-friendliness,

and, above all, Profitability of manufacturing tools.

Because they are so versatile, roll bending and prebending machines are used all over the world in a wide range of sectors: industry, transport, civil engineering, aeronautics, energy, and construction. According to their equipment, these machines are equally suited to single-item production or short or long production runs.

DEVELOPMENT

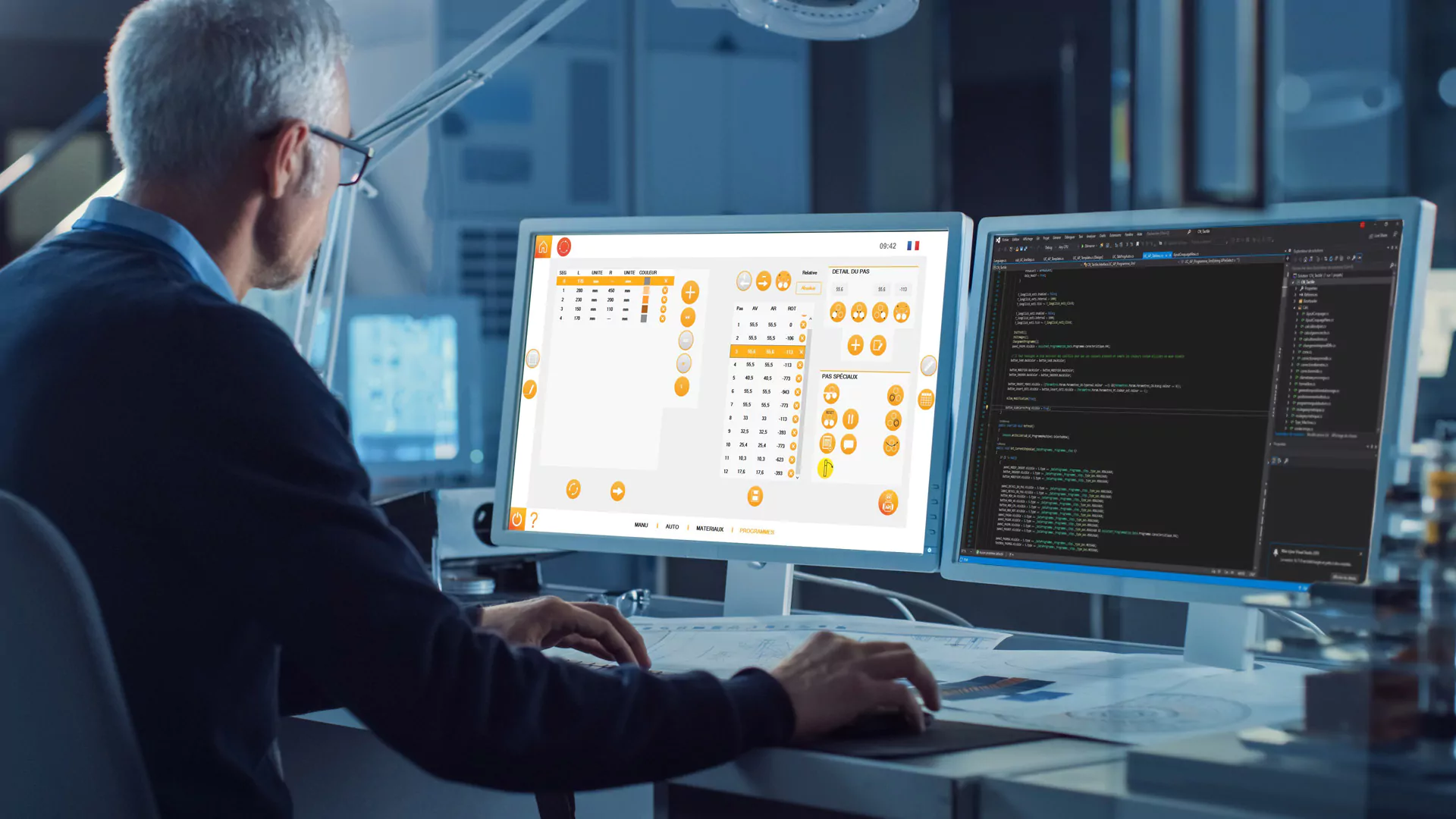

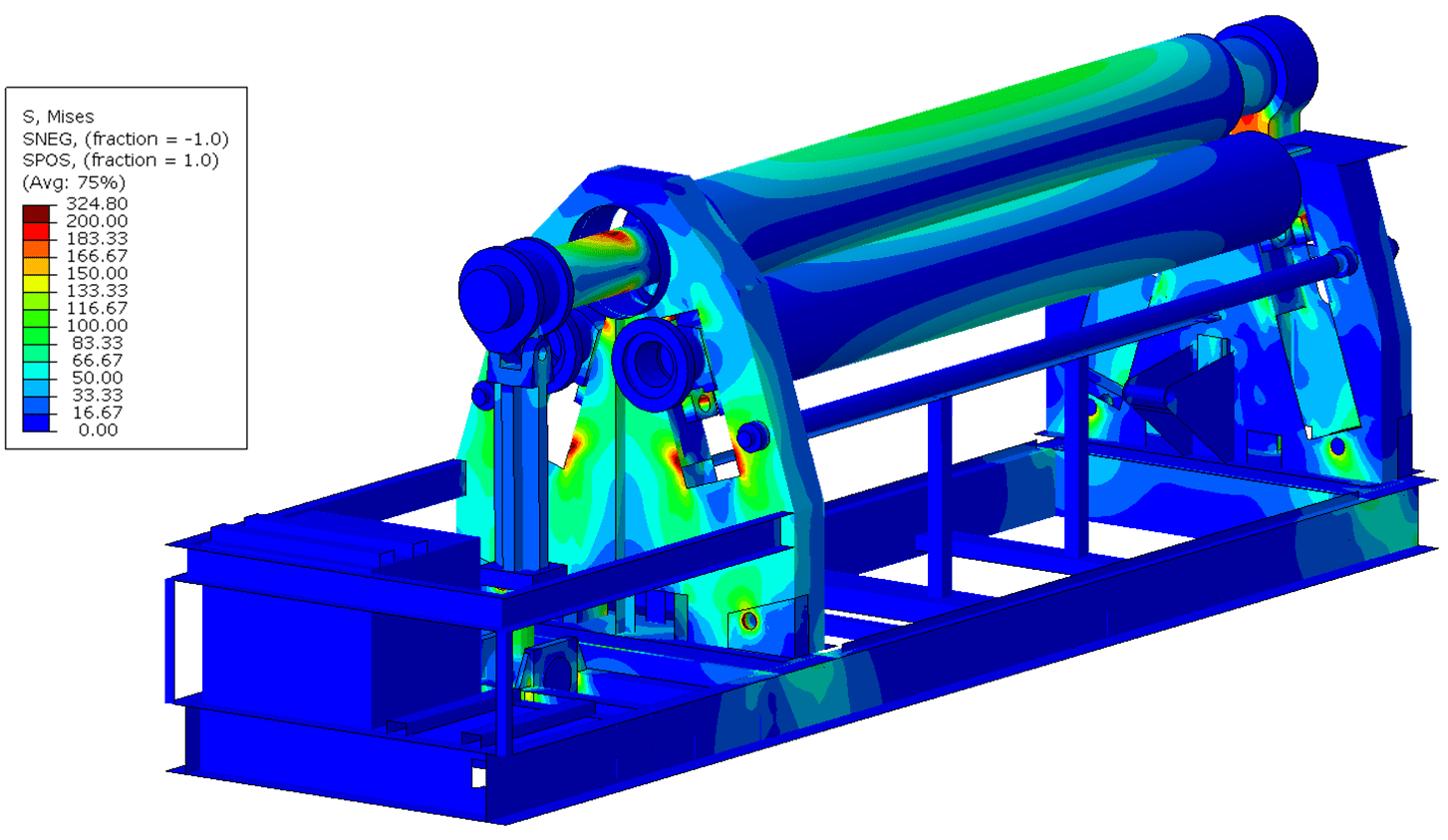

Picot develops its new products and constantly improves its range using 3D design software and finite element analysis. From the mechanical structure to the Numerical Control part, everything is designed by our design office in Lentilly (France).

Picot technologie is essentially:

- Each roller is powered by a hydraulic gearmotor and controlled by a DANFOSS® proportional distributor ensuring a variable and synchronised speed.

- Guideway-mounted rollers with direct cylinder positioning for maximum efficiency.

- Hydraulic or electronic synchronisation of the parallelism of the rollers (Picot patent). This also provides control of roller tilting in both directions (cone rolling, truing).

- NC technology developed by Picot.

Machines can be fitted with the options needed to meet customers’ needs: Deep hardened rolls, hydraulic opening head, end stop and roll control for cone rolling, special control consoles (from compact machine-end mounted hydraulic models to mobile Numerical Control consoles).

All Picot roll bending machines comply with European safety standards and bear the CE Marking.