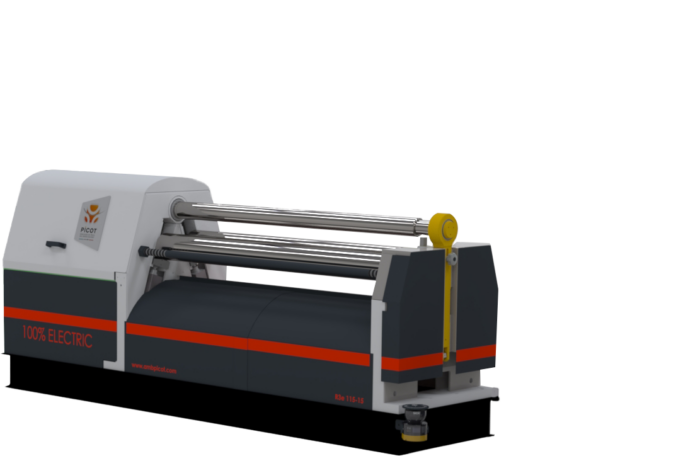

Picot engineers

have developed

a real GPS dedicated

for roll bending

- PLATE BENDING MACHINES -

in line with your plans

Using proven technologies and the latest technical innovations, AMB Picot designs and manufactures machines in France.

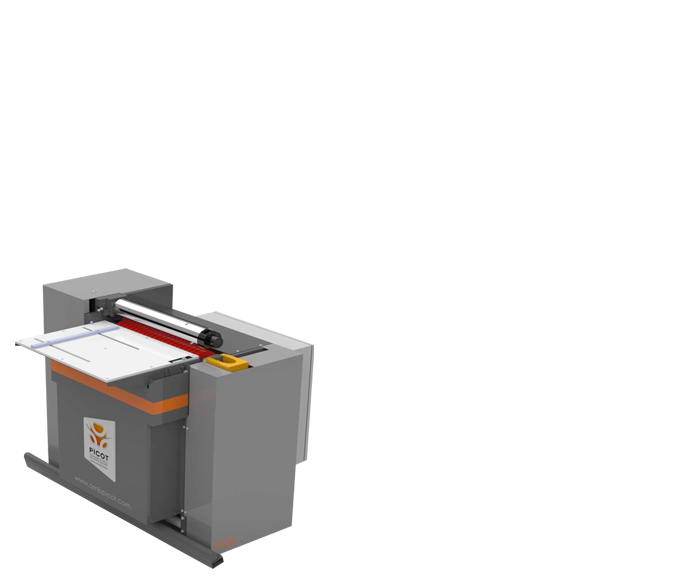

Human/Machine

Interface

With its ergonomic, user-friendly HMI, easyroll® integrates driving and technological innovations into intelligent, predictive, learning and adaptable digital assistance software.

Discover our range of control peripherals designed to meet your needs. Survolez l’image pour en savoir plus sur le pupitre sélectionné…

Contact us >

Pupitre Easyroll - Assistance au roulage