Picot engineers

have developed

a real GPS dedicated

for roll bending

- PLATE BENDING MACHINES -

in line with your plans

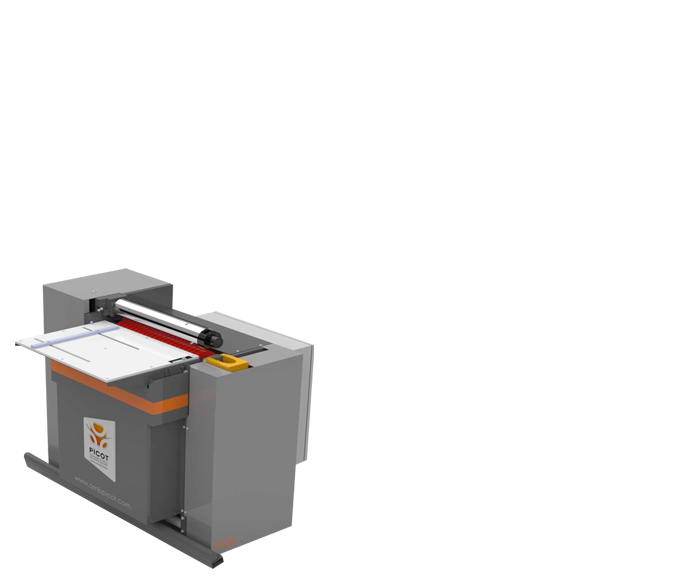

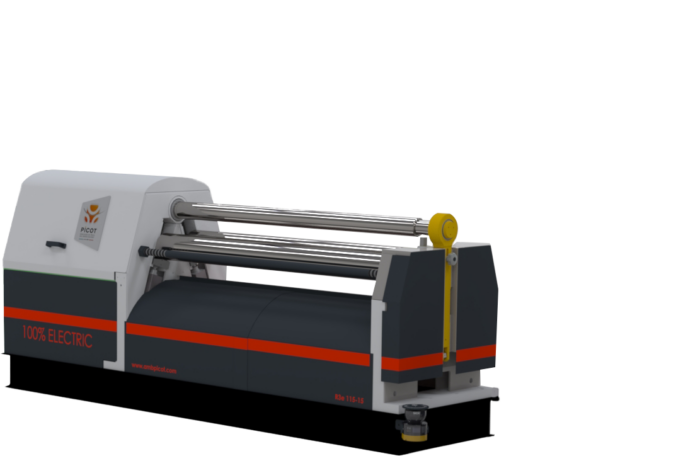

Using proven technologies and the latest technical innovations, AMB Picot designs and manufactures machines in France.

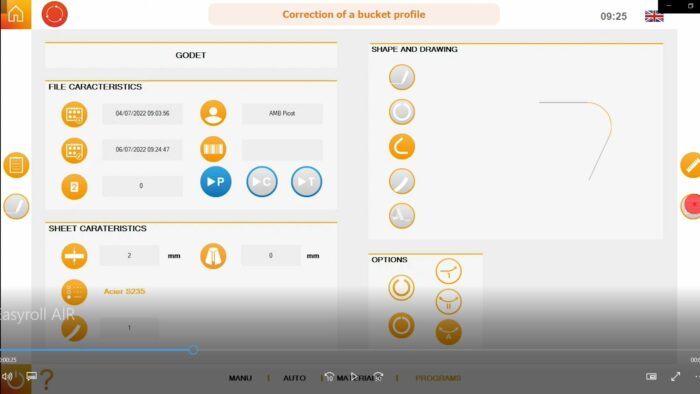

Human/Machine

Interface

With its ergonomic, user-friendly HMI, easyroll® integrates driving and technological innovations into intelligent, predictive, learning and adaptable digital assistance software.

Discover our range of control peripherals designed to meet your needs. Hover over the image to find out more about the selected console...

Contact us >

- Easyroll rolling assistant

- Smart material database

- Calculation of springback

- Cone rolling assistant

- Assisted design & .DXF

- Automatic correction with AIR mode (Artificial Intelligence for Rollbending machines)

Our consoles are designed for plug & play operation: no action required on your machine.

-

Same comfort + NC learning

-

Excellent repeatability of bending by process duplication (high-volume production).

-

Memory capacity: 500 5-steps programs

-

USB key (to back up programs and settings)

Our consoles are designed for plug & play operation: no action required on your machine.

-

Optimum control of all roller movements (roller movement actuated by progressive flow electrohydraulic valves)

-

Controls located on a mobile console (so the operator can move around the machine).

- Movements controlled directly by manually-operated progressive flow hydraulic valves

- Controls located on the right-hand side of the frame on the end of the machine (excellent visual monitoring)

PICOT ENGINEERS have developed an innovative software, a real GPS dedicated for roll bending

Smart material database

All the cards to roll better,

with complete peace of mind

The AIR algorithm and the intelligent material base of Easyroll® are the two pillars of the technology developed and patented by AMB PICOT to predict the rolling performance with unrivalled reliability.

This technology increases the capabilities and scalability of the digital support offered to the user, notably through simulation functions, programming and coning support, springback prediction on 3-roll machines, etc.

Predictive learning

patented technology

Learn, predict and optimise

rolling performance

The characteristics and thicknesses of materials (steel, stainless steel…) and their typical advanced rolling behaviour are integrated in easyroll®. This data can be modified or enhanced by software updates or customised by the user.

AIR: Artificial Intelligence

for Rollbending machine

Improve and capitalise

Rolling experience

easyroll® features an intelligent expert algorithm that helps both the user and the machine to correct errors, stabilises programme performance and transforms personal experience into modelable, reproducible know-how. Yielding point, breaking point, unwanted deformation… AIR goes beyond a simple material correction update and allows you to adapt your easyroll® to your specific needs (fine tolerances, tanks, aircraft fuselage…).

On-board and remote

support

For controllable and mastered

rolling

easyroll® integrates and supports the practical and technological developments of tomorrow’s industry. Innovation and continuous improvement are in its DNA. Proven plug-and-play system (MES connection, etc.) Networked learning machines Advanced machine monitoring (self-diagnostics, customised reports, etc.) Remote support in a real-life environment using the integrated camera of the Picot academy: expert training, active user community, etc.