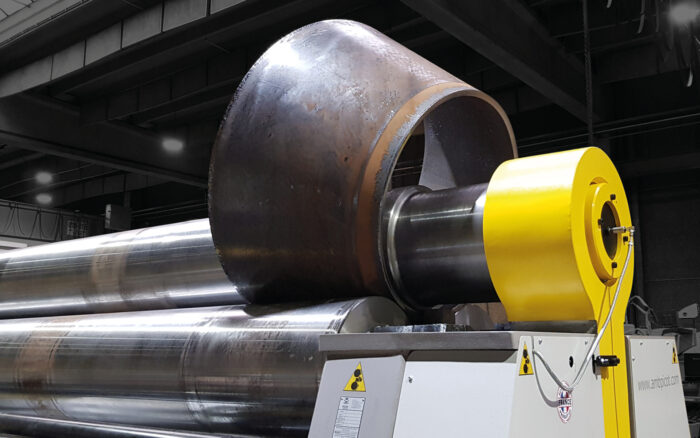

SHEET BENDING MACHINE with three symmetric roller technology R3

Versatility and performance

2, 3 or 4 rollers? Understand the specific features of each technology

There is no such thing as the right or wrong architecture for a machine.

Each roller has its speciality.

Enclosed you will find the different types of processes and your material and performance requirements, grouped by machine type:

- Mass production capability with the R2

- Versatility and performance with the R3

- Mastery of heavy thicknesses and an integration into your processes for the R4

The solution to your problem... and more

If you have a shortage of qualified operators and you are looking for a machine that offers superior performance, the R3 three-roller sheet bending machine (symmetrical three-roller architecture providing double prebending without turning the sheet over) is sure to satisfy your needs.

Its ability to roll thin materials without laminating the sheet and its prebending performance with a limited residual flat edge are thanks to its special symmetric architecture. Thanks to its linear guide system (specific angle) and its bearing system with bronze rings, we guarantee high-quality rolling with regard to sheet edge straightness and cylindrical roundness.

The R3 sheet bending machine is especially recommended for:

- working on single items with high added value (in combination with the Easyroll control system)

- thin sheets and decorative work (design)

- operations with strict requirements concerning geometry (cylindrical roundness, straightness, etc.) and repeatability.

- Work on conical parts

- 3D parts (honeycomb, extruded, perforated)

- materials that are difficult to grasp (with the Easyroll control system and its predictive material database): aluminium, stainless steel, Hardox, etc.

The R3 bending machine has almost unlimited scope. Its wide capacity range, from 0.5 to 40 mm thickness and up to 6 m length, makes it versatile enough to use for almost any application.

R3 Next Gen: a new standard to support your industrial challenges and evolution

- Architecture with 3 independent powered rollers mounted on bronze rings

- Connectivity 4.0 for remote operation and interfacing with your organisation

- Easyroll ready as standard (all of our machines are upgradeable by a Plug & Play console change without other modifications)

- Easyroll: our patented software! Like a GPS to guide you through the bending process. Updates and new versions are provided free of charge.

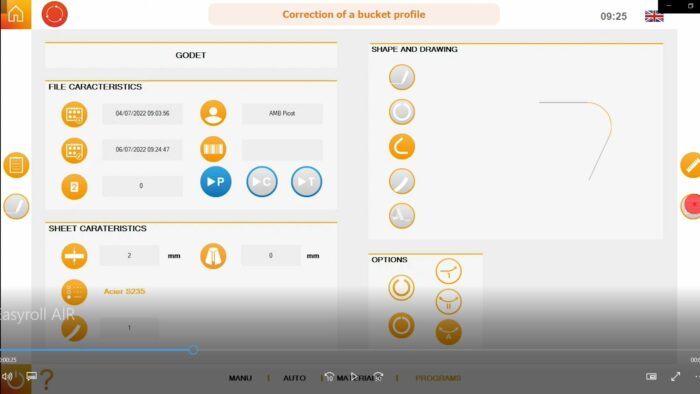

- AIR: Artificial intelligence for Roll bending machine, an extension of Easyroll since V4

- 100% electric R3e version is possible up to 10 mm or Danfoss-equipped hydraulics (100% progressive movements).

What are the advantages of SHEET BENDING MACHINE with three symmetric roller technology

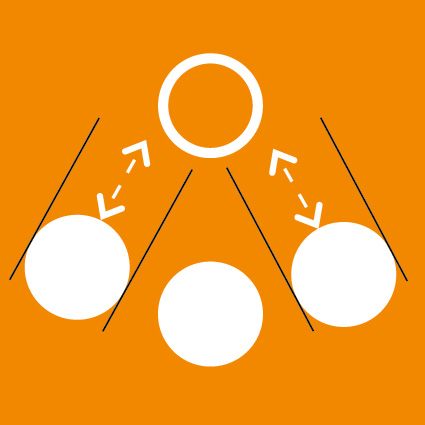

High-performance prebending

Bending of perforated or fragile sheets

Rolling of thick cones

Human/Machine

Interface

With its ergonomic, user-friendly HMI, easyroll® integrates driving and technological innovations into intelligent, predictive, learning and adaptable digital assistance software.

Discover our range of control peripherals designed to meet your needs. Hover over the image to find out more about the selected console...

Contact us >

- Easyroll rolling assistant

- Smart material database

- Calculation of springback

- Cone rolling assistant

- Assisted design & .DXF

- Automatic correction with AIR mode (Artificial Intelligence for Rollbending machines)

Our consoles are designed for plug & play operation: no action required on your machine.

-

Same comfort + NC learning

-

Excellent repeatability of bending by process duplication (high-volume production).

-

Memory capacity: 500 5-steps programs

-

USB key (to back up programs and settings)

Our consoles are designed for plug & play operation: no action required on your machine.

-

Optimum control of all roller movements (roller movement actuated by progressive flow electrohydraulic valves)

-

Controls located on a mobile console (so the operator can move around the machine).

- Movements controlled directly by manually-operated progressive flow hydraulic valves

- Controls located on the right-hand side of the frame on the end of the machine (excellent visual monitoring)

PICOT ENGINEERS have developed an innovative software, a real GPS dedicated for roll bending

Smart material database

All the cards to roll better,

with complete peace of mind

The AIR algorithm and the intelligent material base of Easyroll® are the two pillars of the technology developed and patented by AMB PICOT to predict the rolling performance with unrivalled reliability.

This technology increases the capabilities and scalability of the digital support offered to the user, notably through simulation functions, programming and coning support, springback prediction on 3-roll machines, etc.

Predictive learning

patented technology

Learn, predict and optimise

rolling performance

The characteristics and thicknesses of materials (steel, stainless steel…) and their typical advanced rolling behaviour are integrated in easyroll®. This data can be modified or enhanced by software updates or customised by the user.

AIR: Artificial Intelligence

for Rollbending machine

Improve and capitalise

Rolling experience

easyroll® features an intelligent expert algorithm that helps both the user and the machine to correct errors, stabilises programme performance and transforms personal experience into modelable, reproducible know-how. Yielding point, breaking point, unwanted deformation… AIR goes beyond a simple material correction update and allows you to adapt your easyroll® to your specific needs (fine tolerances, tanks, aircraft fuselage…).

On-board and remote

support

For controllable and mastered

rolling

easyroll® integrates and supports the practical and technological developments of tomorrow’s industry. Innovation and continuous improvement are in its DNA. Proven plug-and-play system (MES connection, etc.) Networked learning machines Advanced machine monitoring (self-diagnostics, customised reports, etc.) Remote support in a real-life environment using the integrated camera of the Picot academy: expert training, active user community, etc.

SHEET BENDING MACHINE with three symmetric roller technology is an asset for your market

Picot sheet bending machines are used in all sectors of industry, construction and even design. Below, you'll find a description of your trade, examples of our customers and the key information you need to answer any questions you may have.